Toolroom Precision, CNC Setup Flexibility!

If you have been involved in CNC machining for very long you know you need to setup the machines quick, you want simple solutions that work, and you want rugged, precision fixturing products that last the lifetime of your CNC. Tosa Tool Modular Subplates and accessories are the easiest way to get your perfect virtual designs out of your cad/cam and into reality. SLASH setup times, IMPROVE quality, and MAXIMIZE the capabilities of your machine tool investment, and your time.

“Its like the job is half done before I go out to the shop!”

When my customers ask me why they should invest in modular fixturing, its the first thing I say “Its like the job is half done before you walk out to the shop!”. Its true, the minute someone shows me a design, whether its a customer, my neighbor with an idea, or my wife with a request for something simple, I immediately start thinking about how easy it will be to setup with my modular fixturing. By the time I am doing the job I know how to get it done easily with the Tosa Tool modular system, and I don’t have to order materials and spend a lot of money on supplies for every job. I use the same basic pieces on every one. – Dan Bye Machinist/CNC Programmer/Toolroom Machinist/ SolidWorks CSWA/BABA. Justification from the Society Of Mechanical Engineers

Advantages

Most of the small mill owners I have met are constantly developing ideas and considering machining new things on their mill. These types of mill owners will quickly realize the benefits of a Tosa Tool modular fixturing system. Parts will be set up faster with a higher degree of accuracy and a significant cost savings over current methods.

Highly Accurate

Exceedingly tight tolerances between bore centers (± 0.01 mm / ±0.0004”) give users the confidence that modular fixtures built today can be rebuilt a month, a year or a decade later to pinpoint accuracy.

Ultimate in Flexibility

With just one set of modular tooling, an unlimited number of fixtures can be built. In addition, changes can quickly be made on the fly during the prototyping process.

Cost Savings

A single purchase of a modular fixturing system can easily last as long as the lifespan of a CNC machine. Imagine never having to worry about fixturing costs again. Our system is designed with precision ground and hardened components to be reused over and over for years to come.

Time Savings

A typical modular fixture can be designed, built and ready to run the first piece in under an hour whereas dedicated fixtures often require days or weeks to be completed. Rebuilding a modular fixture that has already run parts in the past is even faster, taking only minutes to assemble.

Organized Storage

Racks of rusting dedicated fixtures will become a distant memory. A single package of modular fixturing can be neatly stored and organized inside lockable drawers in a workbench. No more wasted time in looking around the shop for missing fixtures.

Highly Innovative

With decades of experience our engineers are available to help solve any fixturing problem. Many new components are a result of collaborative efforts with our customers.

Modular Fixturing

The idea behind Modular Fixturing is simple: Eliminate the hassle and cost of dedicated fixtures and their maintenance, and replace them with precision, flexible components.

Tosa Tool expands upon these core concepts with a unique array of modular tooling plates, a diverse set of components to go with them, and the ability to create your own plates and components if you desire.

CAD/CAM Integration

Every Tosa Tool Modular Sub Plate and component CAD Solid file is available in any format you require. All of our components are designed in SolidWorks, but we can easily convert them to any format you require. Assemble your entire setup virtually before you pull out the toolbox.

Easy Expandability

Want to machine something that is bigger than the work envelope on your CNC? This is where your Tosa Tool Modular plate really excels! Simply make your self a plate that fits your workpiece and the modular table and move it around inside the mills work envelope! Because the Modular Plate is SO accurate you can move your project many times and keep all the accuracy! Its like having a much bigger machine. Wish you had a pallet changer to maximize your productivity? It is extremely easy to build one around your Tosa Tool Modular Fixturing Sub Plate. Contact us for solutions to your specific situations!

Read the Justification for Modular Fixturing from the Society Of Mechanical Engineers In Dearborn, MI here: SME on MODULAR FIXTURING

Modular Accessories

When you shop for a modular fixturing system be sure the company you choose offers a complete line of fixturing components that work with your hole pattern and are rugged and designed for long life. They should offer Vises, Angle Plates, Tombstones and components that allow easy setups for flatwork as well. Modular Fixturing is only as good as the products that work with your plate. Some you will need to build, but your plate supplier should offer many standard accessories and hardware. Tosa Tool has been designing and building Modular Fixturing Plates and Components since 1992. We will also quote your designs, and work with you on your ideas and modular needs.

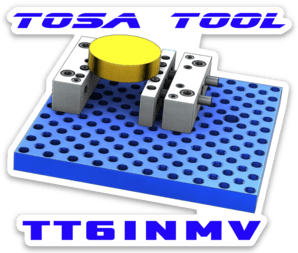

See the Tosa Tool 6″ Modular Vise here: TT6INMV